Teams are a group of individuals working together to achieve a common goal. The best team can be multifunctional and include people from diverse cultural backgrounds and belief systems. The best way to build a great team is by encouraging and developing each member. The key to success in any business is a cohesive and well-organized team.

Teamwork is key to achieving a common goal

It is essential to work in a team and achieve a common goal. Every member of the team must contribute their knowledge and skills to make teamwork possible. It's nearly impossible to achieve a common goal without teamwork. There are many ways to encourage teamwork.

A way to increase teamwork is to look at the bigger picture. A common goal can be difficult to define when individuals have different backgrounds and approaches. To understand what everyone is focused on, it's important to have an open and honest dialogue. This will allow everyone in the group to achieve the same goal and help them to be more successful.

Five stages of team-building

The team members have learned to cooperate and have built trust and respect among each other. As they become more comfortable with each other and their work style, they become more efficient and productive. The leader at this stage is usually only there to keep an eye on the team's progress and not get involved in the details.

Leaders should work to build long-lasting relationships with their team and celebrate the project's success. The team might be asked to accept new responsibilities like overseeing the project's completion.

Good team members are characterized by certain characteristics

A good team member is flexible, willing to work with others, and has the ability to hold themselves accountable. In addition, the ideal team member has a learning mindset and is never afraid to challenge their assumptions and opinions. He or she is open to admitting when he/she is wrong. He or she must also be open to sharing the spotlight with others and being a role model for younger members of the team.

A team member who is effective listens to their colleagues and communicates clearly without interrupting others. This is essential for teamwork success as it fosters honest and open communication. It allows members of the team to openly discuss their problems and share their ideas.

Understanding your team members

It is essential to first learn about each individual's preferences if you are going to improve your team's performance. This is done through the DiSC Assessment. This allows you to assess each team member's motivations, stressors, default behaviors and other motivators. It can also help to understand and communicate better with team members, which will lead to positive working relationships.

To foster a positive work environment, it is vital to get along with your team. If team members get to know one another, they are more likely to be able and willing to support one other and work together towards a common goal. One example is that a team who understands each other's strengths can work more effectively to resolve conflicts. It will also reduce stress and make it easier to work more efficiently.

FAQ

What is the meaning of "project management?"

That is the management of all activities associated with a project.

We help you define the scope of your project, identify the requirements, prepare the budget, organize the team, plan the work, monitor progress and evaluate the results before closing down the project.

What are management concepts?

Management concepts are the fundamental principles and practices that managers use when managing people and their resources. They cover topics such as job descriptions and performance evaluations, human resource policies, training programs, employee motivation, compens systems, organizational structure, among others.

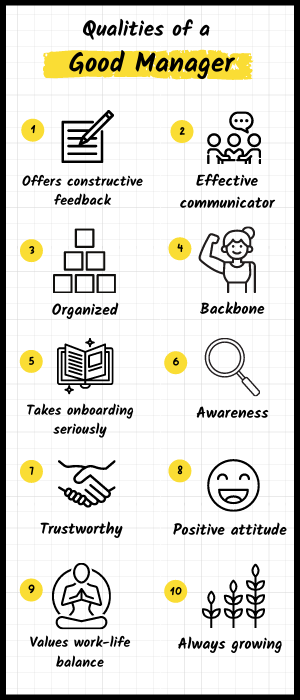

How do you manage your employees effectively?

Effectively managing employees requires that you ensure their happiness and productivity.

This includes setting clear expectations for their behavior and tracking their performance.

Managers need to establish clear goals for their team and for themselves.

They need to communicate clearly and openly with staff members. They must communicate clearly with staff members.

They also need to keep records of their team's activities. These include:

-

What did we accomplish?

-

How much work were you able to accomplish?

-

Who did it?

-

It was done!

-

Why was it done?

This information can be used for monitoring performance and evaluating results.

What is the role of a manager in a company?

There are many roles that a manager can play in different industries.

In general, a manager controls the day-to-day operations of a company.

He/she will ensure that the company fulfills its financial obligations.

He/she makes sure that employees adhere to the rules and regulations as well as quality standards.

He/she plans new products and services and oversees marketing campaigns.

What is Six Sigma and how can it help you?

It's a strategy for quality improvement that emphasizes customer care and continuous learning. This is an approach to quality improvement that uses statistical techniques to eliminate defects.

Motorola created Six Sigma as part of their efforts to improve manufacturing processes in 1986.

The idea spread quickly in the industry. Today many organizations use six-sigma techniques to improve product design.

Statistics

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing processes are used to reduce waste and improve efficiency through structured methods. They were developed in Japan by Toyota Motor Corporation (in the 1980s). The main goal was to produce products at lower costs while maintaining quality. Lean manufacturing seeks to eliminate unnecessary steps and activities in the production process. It is made up of five elements: continuous improvement, continuous improvement, just in-time, continuous change, and 5S. Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is constantly improving upon existing processes. Just-in–time refers when components or materials are delivered immediately to their intended destination. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Last but not least, 5S is for sort. To achieve the best results, these five elements must be used together.

Lean Production System

Six key concepts are the basis of lean production:

-

Flow - The focus is on moving information and material as close as possible to customers.

-

Value stream mapping - break down each stage of a process into discrete tasks and create a flowchart of the entire process;

-

Five S's, Sort, Set in Order, Shine. Standardize. and Sustain.

-

Kanban is a visual system that uses visual cues like stickers, colored tape or stickers to keep track and monitor inventory.

-

Theory of constraints: identify bottlenecks in your process and eliminate them using lean tools, such as kanban board.

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement - incremental improvements are made to the process, not a complete overhaul.