If you're interested in reducing your carbon footprint and lowering your supply chain's emissions, here are some of the most common methods you can employ. These include: Engaging stakeholders; Managing sustainable procurement; and addressing social responsibilities. These tips will help you build a more predictable and sustainable supply chain.

Stakeholder Engagement

Successful engagement with stakeholders is vital to the success of any company's sustainability efforts. In fact, engaging stakeholders can speed up the sustainability journey. Companies can foster a collaborative culture by implementing solid engagement strategies. They can also work well with multiple stakeholders. Engagement with stakeholders is a great way to improve the supply chain and gain valuable insights into potential risks and opportunities.

In order to engage stakeholders in a sustainable supply chain, companies should carefully select the metrics they are interested in tracking. It is crucial to take into consideration the social and ecological aspects of a business when choosing metrics. Environmental and social metrics can be difficult to measure for any company. It is also possible that many stakeholders are not aware of the company’s sustainability efforts. This makes engagement challenging.

Managing sustainable procurement

Managing sustainable procurement is an important process for any company. It is important that transparency is maintained throughout the supply chain. Tier 1 suppliers should also be held accountable for implementing sustainable practices. Some organizations struggle to implement sustainable practices due to a lack of visibility into their supply chain. A recent survey by EcoVadis revealed that only half of organizations had complete visibility into their supply chains, and that 28% did not have this kind of visibility at all. Implementing sustainability measures can take many years. However, organizations can start with small wins like auditing suppliers.

By making sustainable procurement a standard part of the procurement process, procurement teams can minimize risks, identify incremental improvements, and ensure that internal customers are aware of the impact of their purchases. To achieve sustainability, organizations need to go beyond the existing options and develop and implement new ways of sustainable procurement. They must also work in new ways with suppliers, learn new skills, and ensure that they have the right data and information to achieve their goals.

Managing social responsibility

Every sustainable supply chain includes social responsibility (CSR). CSR principles must be followed at every step of the supply chain. Businesses must collaborate to ensure that their products and services do not adversely affect the environment. This includes assessing product lifespan phases, developing reuse strategies, and developing transportation abilities. Companies must also consider the needs of their customers and comply with all applicable regulations.

While sustainability refers to meeting current and future needs, it can also include economic, social, and environmental issues. Social responsibility is a commitment of a business to conduct business ethically, to benefit its workforce, local community, society, and the wider world.

FAQ

What are the key management skills?

Business owners need to have management skills, no matter how small or large they may be. They are the ability to manage people and finances, space, money, and other factors.

These skills are necessary for setting goals and objectives as well as planning strategies, leading groups, motivating employees and solving problems.

As you can see, there's no end to the list of managerial duties!

What can a manager do to improve his/her management skillset?

By practicing good management skills at all times.

Managers should monitor the performance and progress of their subordinates.

It is important to take immediate action if your subordinate doesn't perform as expected.

You should be able to identify what needs improvement and how to improve things.

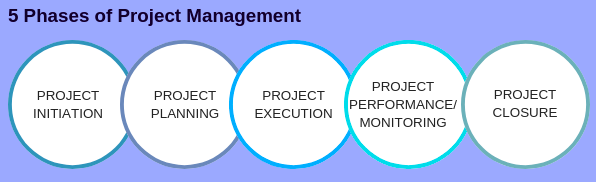

Why is project management so important?

Project management techniques can be used to ensure smooth project execution and meeting deadlines.

Because most businesses depend heavily on project work to produce goods or services,

These projects are essential for companies.

Without effective project management, companies may lose money, time, and reputation.

Statistics

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

External Links

How To

How do you do the Kaizen method?

Kaizen means continuous improvement. Kaizen is a Japanese concept that encourages constant improvement by small incremental changes. It's where people work together in order to improve their processes constantly.

Kaizen, a Lean Manufacturing method, is one of its most powerful. The concept involves employees responsible for manufacturing identifying problems and trying to fix them before they become serious issues. This is how you can improve the quality and lower the cost.

Kaizen is an approach to making every worker aware and alert to what is happening around them. So that there is no problem, you should immediately correct it if something goes wrong. Report any problem you see at work to your manager.

Kaizen has a set of basic principles that we all follow. When working with kaizen, we always start with the end result and move towards the beginning. If we want to improve our factory for example, we start by fixing the machines that make the final product. Then, we fix the machines that produce components and then the ones that produce raw materials. We then fix the workers that work with those machines.

This method is known as kaizen because it focuses upon improving every aspect of the process step by step. When we are done fixing the whole factory, we go back to the beginning and continue until we reach perfection.

To implement kaizen in your business, you need to find out how to measure its effectiveness. There are several ways to determine whether kaizen is working well. Another method is to see how many defects are found on the products. Another way is determining how much productivity increased after implementing kaizen.

Another way to know whether kaizen is working is to ask yourself why did you decide to implement kaizen. You were trying to save money or obey the law? You really believed it would make you successful?

Suppose you answered yes to any of these questions, congratulations! You are ready to start kaizen.